Cotton quality – from the field to ginning and spinning

Yarn and raw material quality is the basis for all types of textile products. With the focus on cotton quality and quality testing, the effect of ginning and cleaning in the preliminary stage, as well as innovations in spinning technology, the conference is dedicated to its origins. Scientists and practical experts from around the globe will present the latest developments along with promising research findings.

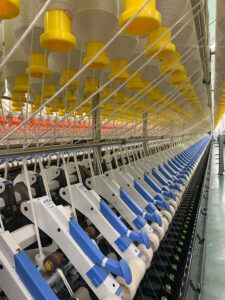

Quality production in spinning and textile processing

Ring spinning – © Photo: Jean-Paul Haessig, Asian Cotton Traders

Ring spinning is one of the leading, most versatile methods for producing yarn from different materials. Mahmud Hossain from the Institute of Textile Machinery and High Performance Material Technology at the Technical University in Dresden will present a procedure developed in conjunction with the Leibnitz Institute of Polymer Research in Dresden, which eliminates the friction generated during the twisting of spun thread.

Hemp and cotton in spinning: Ralf Müller from the textile machinery manufacturer Trützschler, Mönchengladbach, will illustrate in his presentation how these natural fibres can be spun together to form quality yarns.

There is great anticipation surrounding the lecture by Jaswinder Bedi, one of the leading figures of various textile associations on the African continent. He is also the CEO of Bedi Investments Ltd. and Executive Director of Fine Spinners Uganda Ltd.

Have look at the session in the programme: Spinning and Textile Processing

Testing cotton quality – from field to preliminary stage

Impurities in seed cotton © Photo: Axel Trede, CSI

Recurring problems with the stickiness of supplied cotton can result in considerable disruptions to the process, reducing the productivity of procedures in the textile industry. Jean-Paul Gourlot from the French Agricultural Research Centre for International Development (CIRAD) in Montpellier will present the latest findings as a member of the International Committee on Cotton Testing Methods (ICCTM).

Mourad Krifa from Kent State University, Oklahoma, USA will make clear how typical impurities in seed cotton, e.g. due to leaf and bark residues, grass or seed coat residues as well as dirt, can affect the test results of High-Volume Instrument (HVI) tests.

Deninson Lima from the Brazilian Cotton Growers Association ABRAPA in Brasilia will report on the development of the ‘Standard Brazil HVI Programme’ (SBRHVI). In international competition, ABRAPA drove forward a universal instrumental quality test that complied with international standards.

Efstratios Fragkotsinos from Swiss test instrument manufacturer Uster Technologies will emphasise the importance of cotton bale management in spinning mills. Cotton usage can be optimised in relation to the desired fibre and yarn qualities as well as the storage space used.

Have look at the session in the programme: Cotton Quality and Testing

Cotton ginning and its effect on fibre quality

Measuring the moisture of cotton in the testing lab © Photo: Bremen Cotton Exchange

Justin Kühn from the Institute of Textile Technology at RWTH Aachen University will ask whether the methods for controlling the raw material moisture at pre-spinning stage or during the ginning process have a decisive influence over fibre quality. He will present findings from the latest scientific research.

In his presentation, Marinus van der Sluijs from Textile Technical Services in Australia will compare the results of cleaning cotton at ginning stage with those during preliminary stages at the spinning mill. The at first glance astonishing conclusion is that cotton that was cleaned the least makes for a better-quality yarn, irrespective of the chosen cleaning stage.

Derek Whitelock from the USDA-ARS Southwestern Cotton Ginning Research Laboratory La Cruces in New Mexico, USA will present the findings of more recent tests carried out by his institute on various types of ginning machines, comparing the material quality achieved with Pima and Upland cotton.

Jaya Shankar Tumuluru, also from the USDA-ARS Southwestern Cotton Ginning Research Laboratory, will clarify within the scope of a study how the use of a pneumatic fractionator for cotton ginning affects the fibre quality of Upland cotton.

Have look at the session in the programme: Ginning News