– Genetic Engineering Today

– Robot and Satellite Technology in Practice

– Pure Agriculture: Seed Cultivation, Growing, Ginning

Bremen, 19 February 2021: On 17 and 18 March, the doors will open for the International Cotton Conference Bremen – The Hybrid Edition. This time around, the meeting point of the global cotton and textile world will be mainly virtual.

Cotton field © Bremen Cotton Exchange

Wherever we look, transparency is being demanded along for the entire supply chain. Today, knowledge about cotton and its cultivation is not only important for raw material producers and the textile sector, but also increasingly for retail, as the key to the end consumer. Here, the conference has a lot to offer during two sessions in the afternoon on 17 March.

Robots and Satellite Technology in Cotton Cultivation

Gaylon Morgan, Director of Agricultural and Environmental Research at Cotton Incorporated, Cary, North Carolina, USA, is a specialist in the further development of cotton cultivation methods and leads the conference sessions “Cotton Breeding and Production”. The sessions provide an overview of developments in the field of seed breeding, the use of robots and satellite technology in cotton cultivation and the improvement of ginning processes. The focus is on both ecological and economic sustainability.

Long-Term GMO Study

David Albers, Product Development Manager for Bayer Crop Science in St. Louis, Missouri, USA, provides information on the results of a long-term study on the use of transgenic seeds. This compares yield and quality results from the 1980s, i.e. those directly before the introduction of transgenic seeds, with those from four decades later until today.

Status Quo of African Seed Breeding Systems

Marc Giband, Research Associate at the Agricultural Research Centre for International Development (CIRAD) in Montpellier, France, has taken part in seed breeding projects in West and Central Africa. Together with other African and European scientists, he was involved in extensive analyses of the state of seed breeding development in Africa. The cotton yields on the continent are still well below the world average and there is still great potential here.

Robot Technology is Changing Modern Agriculture

Alex Thomasson is Professor and Department Head of Agricultural and Biological Engineering at Mississippi State University, USA. In his lecture “Robot technology for the cotton harvest” he presents the possibilities of using robots that make the harvesting process more productive and reduce CO² emissions by using fewer large machines. For example, robot harvesters can perform multiple harvesting procedures within the growing season, during which they only access the ripe, open cotton buds. This reduces crop losses and ensures better fibre quality.

In addition, a poster presentation by Cotton Incorporated draws attention to robots that are used for targeted weeding in the cotton field, which can influence the use of herbicides.

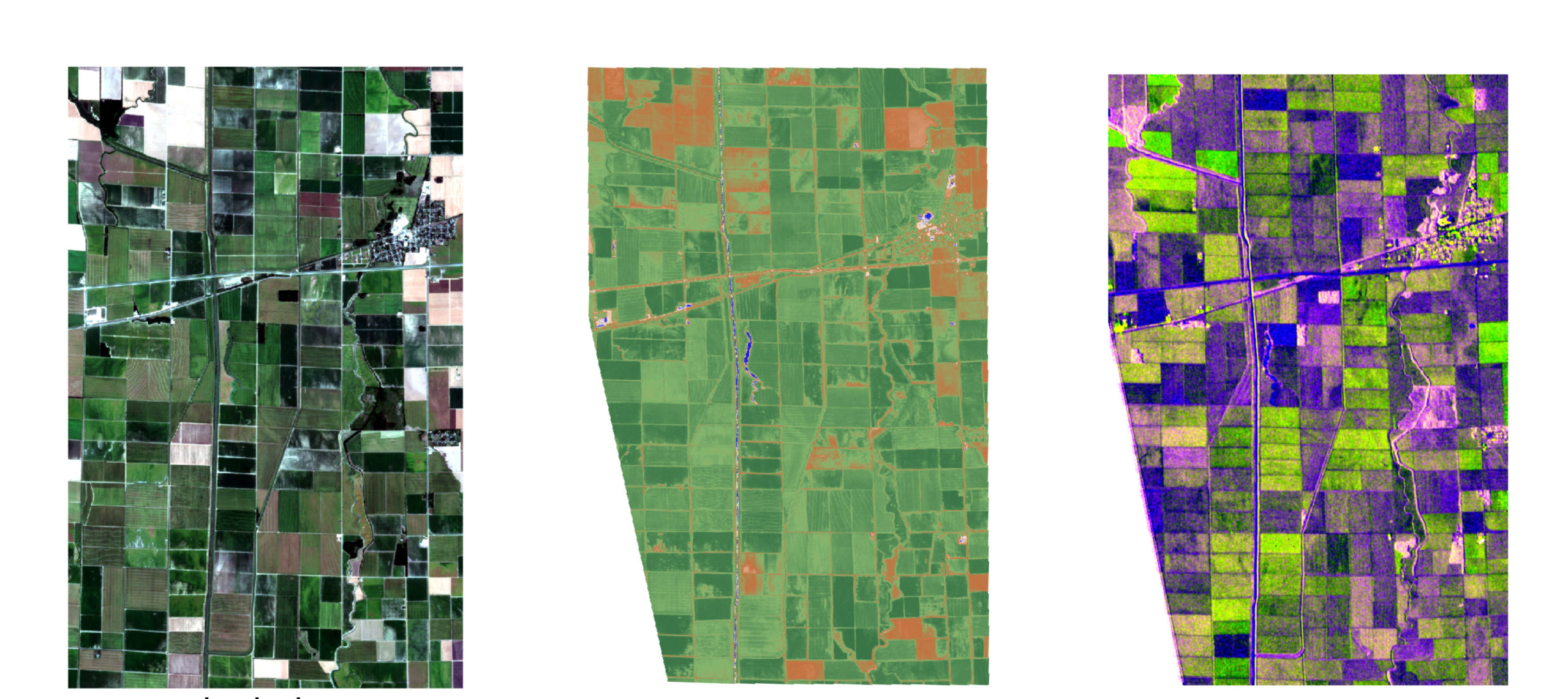

Satellite Images Reveal Plant Growth Problems

Physicist Sabrina Melchionna is the owner of Remote Sensing, Bremen, Germany. She advises companies on ground observation through satellites and data acquisition. Based on satellite data, digital maps are created that provide ecological status images. In her lecture, she presents examples of ground observation images of cotton fields that provide information about plant health and growth. The information from the satellite data can help farmers to work in a resource-optimised manner and to offer higher-quality crops.

Different satellite images of a cotton field in Mississippi © Melchionna – Remote Sensing

Optimising Ginning Processes

In the ginning process, cotton fibres are mechanically separated from the seeds after harvest. Greg Holt heads the Cotton Production and Processes Research Department at the US Department of Agriculture, Lubbock, Texas. In his lecture he shows that contamination by cotton wrapped in plastic can be traced back to round modules deposited in the field after the machine harvest. If the smallest plastic particles remain in the cotton, this leads to defects in the dying of yarns and fabrics, and thus to complaints in the event of product failure.

Carlos B. Amijo from the Agricultural Research Service of the US Department of Agriculture (USDA) in Mesilla Park, New Mexico, provides information on the development of ginning techniques that help ensure that the fibre length uniformity index achieved meets the requirements of newer and more efficient spinning technology. This would provide the textile industry with longer and more uniform fibres, making yarn production more efficient.

We will continue to report on the other contents of the cotton conference and the supporting programme in future press releases. The current conference news and programme details can also be found on the conference website:

https://cotton-conference-bremen.de/program/

We look forward to active media coverage. Interview requests in advance are processed as quickly as possible. We are already inviting journalists to the conference Accreditations are possible via the formular attached to this mailing. It is also available as download on the conference website at any time https://cotton-conference-bremen.de/press/. Please send it filled out to tagung@cotton-conference-bremen.de.

Images contained in the press release may be used for publication provided that the source/author is acknowledged.

For further information and interview requests, please contact:

Bremen Cotton Exchange

Elke Hortmeyer, Director of Communications and International Relations

Tel.: +49 421 3397016 | E-Mail: hortmeyer@baumwollboerse.de

www.cotton-conference-bremen.de | www.baumwollboerse.de

About the International Cotton Conference

The International Cotton Conference Bremen – the Hybrid Edition offers a total of 13 conference sessions covering highly relevant topics from the international cotton textile industry. A new feature of the virtual format is the possibility to choose between two parallel lecture strands: The ‘Conceptual Track’ deals with current challenges and fundamental issues within the industry, while the ‘Technical Track’ is mainly devoted to technological and scientific developments. All sessions are characterised by great opportunities for interaction in the form of moderated chats, surveys and questionnaires.

In addition, the ‘Interaction Track’ provides the opportunity for break-out sessions, poster presentations and individually organised virtual table discussions. A digital matchmaking service, business speed dating and extensive opportunities for discussion groups during breaks round off the networking offers. In addition, the virtual platform makes it possible to send questions to speakers at any time and to arrange to meet interesting contacts for video or audio calls.

Find more information about the virtual experience on the conference website: https://cotton-conference-bremen.de/virtualexperience/

The organisers of the International Cotton Conference Bremen are the Fibre Institute Bremen e. V. (FIBRE) and the Bremen Cotton Exchange.

Download the press release: Progressive cotton farming works like this (pdf)